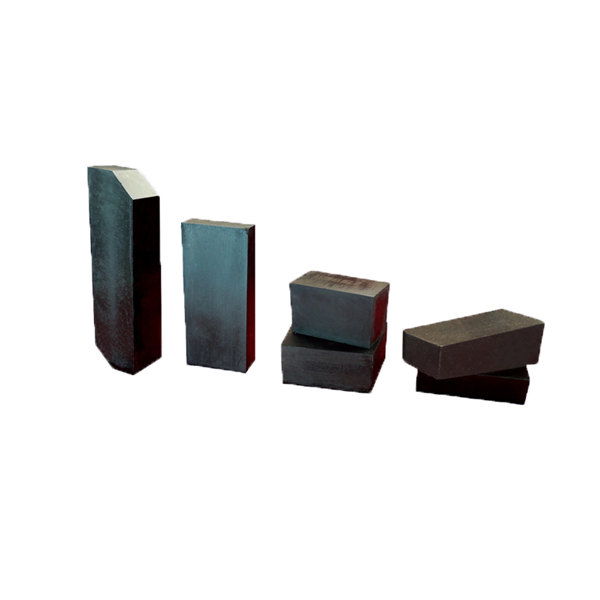

Al2O3-SiC-C bricks

Aluminum Silicon Carbide Carbon Bricks (Al2O3-SiC-C bricks) (ASC bricks for short) are mainly made of dense fused corundum, fused white corundum, brown corundum, tabular corundum, silicon carbide and graphite. Aluminum Silicon Carbide Carbon Bricks (Al2O3-SiC-C bricks) have excellent performance, which is reflected in the resistance to chemical erosion of molten iron and slag and the erosion of molten iron and slag.

Al2O3-SiC-C bricks are used for the lining of molten iron pretreatment equipment such as torpedo-type mixing iron cars and molten iron tanks.

Welcome to inquiry us about the price, size, techinical data and any information you want to know about Al2O3-SiC-C bricks.

Performance Characters:

Good high temperature performance and oxidation resistance

Strong resistance to spalling and slag erosion

1、ASC bricks for ladle

Item/Grade | ASC-1 | ASC-2 | ASC-3 |

Al2O3 % | ≥55 | ≥57 | ≥62 |

SiC+F·C % | ≥17 | ≥14 | ≥10 |

F·C % | ≥8 | ≥6 | ≥4 |

Apparent porosity; % | ≤8 | ≤10 | ≤10 |

Bulk density; g/cm3 | ≥2.75 | ≥2.75 | ≥2.75 |

Cold crushing strength; Mpa | ≥35 | ≥40 | ≥45 |

2、ASC bricks for torpedo tanks

Item/Grade | Top of T/P | T/P S/L and M/L |

Al2O3 % | ≥70 | ≥68 |

SiC % | ≥6 | ≥6 |

C % | ≥6 | ≥9 |

Apparent porosity; % | ≤10 | ≤10 |

Bulk density; g/cm3 | ≥3.0 | ≥3.0 |

Cold crushing strength; Mpa | ≥40 | ≥40 |