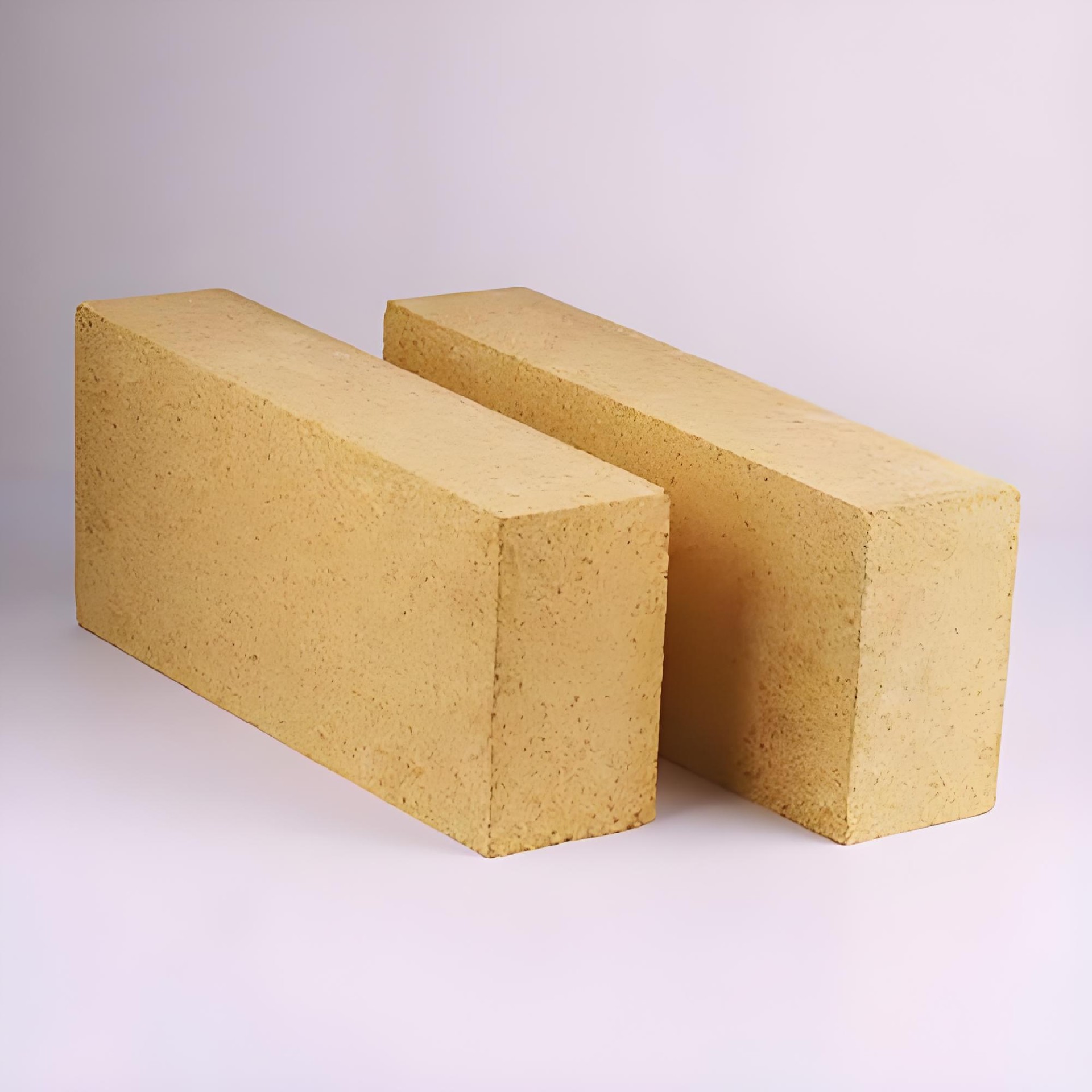

Low creep fireclay refractory brick

MARSREF is a supplier of low creep fireclay refractory brick. The difference between low creep fireclay brick and ordinary clay brick lies in the different production process. Low creep fireclay brick is made of super coke gem, andalusite and mullite as main raw materials, supplemented with special additives, and is formed under high pressure and fired at high temperature. It contains 40% to 48% alumina and has a refractoriness of 1580 to 1770℃.

Low creep fireclay bricks are generally used in high temperature kilns such as blast furnace and hot air blast stoves and aluminum industrial carbon roasting furnaces.

Welcome to inquiry us about the price, size, technical data and any information you want to know about this brick.

Performance Characters:

High heat storage capacity

High refractoriness under load

Good creep performance

Good volume stability under high temperature

Item/Grade | DRN-128 | DRN-125 | DRN-120 | DRN-115 | DRN-110 |

Al2O3 % | ≥45 | ≥45 | ≥42 | ≥40 | ≥36 |

Fe2O3 % | ≤1.8 | ≤1.8 | ≤1.8 | ≤1.9 | ≤2.0 |

Apparent porosity; % | ≤18(20) | ≤20(22) | ≤20(22) | ≤22(24) | ≤22(24) |

Bulk density; g/cm3 | 2.2-2.3 | 2.15-2.2 | 2.15-2.2 | 2.0-2.1 | 2.0-2.1 |

cold crushing strength; Mpa | ≥55(45) | ≥45(35) | ≥35(25) | ≥35(25) | ≥30(20) |

creep in compression 0.2MPa,50h % | 1280℃ 0.8 | 1250℃ 0.8 | 1200℃ 0.8 | 1150℃ 0.8 | 1100℃ 0.8 |

Reheating Linear Change % | 1350℃×2h -0.4~0.1 | 1350℃×2h -0.4~0.1 | 1300℃×2h -0.4~0.1 | 1300℃×2h -0.4~0.1 | 1300℃×2h -0.4~0.1 |

The values in brackets are the data for checker bricks or special bricks | |||||